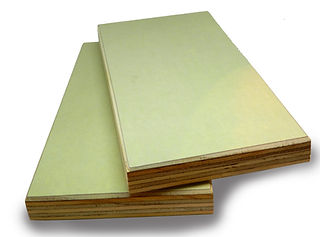

Film Standard

PHENOLIC FILM PANEL

WE ARE STRUCTURAL 1,

23/32 in & 3 / 4 in

Panel overlaid both sides with brown film PSF 125 g/m2.

Up to 10 uses per face

General Specifications

-

Allows up to 20 reuses (requires reasonable care).

-

Overlaid with brown film of 125 g/m2.

-

Recommended for concrete that requires further treatment such as painted, or other coating treatments.

-

High strength and light weight.

-

65% phenolic resin.

Product Features and Applications

-

Tulsa Standard Film panels are edge sealed during manufacturing. If you cut boards during the use, it is recommended to re-seal the fresh edges to avoid panel damage caused by capillary penetration of humidity.

-

Make sure to also use the appropriate form remover or release agent (a chemical reactive releases for nonporous surfaces).

-

Although cleaning a Tulsa overlaid panel is much easier and quicker than traditional form material, it is important to only use fiber spatulas and synthetic materials when cleaning forms to prevent damages to the faces. This damage might occur when using metallic tools. Always store the panels inside a warehouse, protected from weather conditions.

-

Although Tulsa Standard Film panels are very resistant to the abrasion and impact, care must be taken during cleaning and use to prevent damage. Always use the appropriate vibrators and techniques to protect the panel surface.

Size

Thickness:

-

12 mm = 15 / 32''

-

15 mm = 19 / 32''

-

18 mm = 23 / 32''

-

21 mm = 27 / 32''

Dimensions:

-

Width 1,220 m = 4'

-

Length 2,440 m = 8'

-

Width 1,250 m = 4 3/22

-

Length 2,500 m = 8 13/64

Film Premium

PHENOLIC FILM PANEL

Overlaid film for concrete form

Panel overlaid both sides with black film PSF 125 g/m2 + MDO 235g/m2. 15 to 25 uses per face.

General Specifications

-

Allows between 30 to 50 reuses (requires reasonable care).

-

Faces have 125 g/m2 phenolic film overlay + 235 g/m2 MDO film overlay, with a total of 360 g/m2 providing a high quality that assures water resistance and stiffness stability.

-

65% Phenolic resin in overlay film and 27% in MDO.

Product Features and Applications

-

Tulsa Premium Overlay Panel are edge sealed during manufacturing. If you have to cut boards during the use, it is recommended to re-seal the fresh edges to avoid panel damage caused by capillary penetration of humidity.

-

Make sure to also use the appropriate form remover or release agent (a chemical reactive releases for nonporous surfaces).

-

Although cleaning a Tulsa Premium Panel is much easier and quicker than traditional form materials, it is important to only use fiber spatulas and synthetic materials when cleaning forms to prevent damage to the faces. This damage might occur when using metallic tools. Always store the panels inside a warehouse, protected from weather conditions.

-

While Tulsa Premium Overlay Panel are very resistant to the abrasion and impact, care must be taken during cleaning and use to prevent damage. Always use the appropriate vibrators and techniques to protect panel’s surface.

Size

Thickness:

-

12 mm = 15 / 32''

-

15 mm = 19 / 32''

-

18 mm = 23 / 32''

-

21 mm = 27 / 32''

Dimensions:

-

Width 1,220 m = 4'

-

Length 2,440 m = 8'

-

Width 1,250 m = 4 3/22

-

Length 2,500 m = 8 13/64

MDO concrete with Backer

OVERLAID BOARD FOR CONCRETE FORM

Overlaid boards for concrete form

General specifications

Size

-

Allows between 10 reuses (requires reasonable care).

-

Main face with MDO 367 g/m2 and backer 125 g/m2.

-

35% phenolic resin in MDO.

Product Features and Applications

-

Tulsa MDO Concrete Forming panels are edge sealed during manufacturing. If you have to cut boards during use, it is recommended to re-seal the fresh edges to avoid panel damage caused by capillary penetration of humidity.

-

Make sure to also use the appropriate form remover or release agent (a chemical reactive releases for nonporous surfaces).

-

Although cleaning a Tulsa MDO overlaid panel is much easier and quicker than traditional form material, it is important to only use fiber spatulas and synthetic materials when cleaning forms to prevent damages to the faces. This damage might occur when using metallic tools. Always store the panels inside a warehouse, protected from weather conditions.

-

While MDO Concrete Forming panels are very resistant to the abrasion and impact, care must be taken during cleaning and use to prevent damage. Always use the appropriate vibrators and techniques to protect the panel surface.

Thickness:

-

12 mm = 15 / 32''

-

15 mm = 19 / 32''

-

18 mm = 23 / 32''

-

21 mm = 27 / 32''

Dimentions:

-

Width 1,220 m = 4'

-

Length 2,440 m = 8'

MDO concrete forming without Backer

OVERLAID BOARD FOR CONCRETE FORMING

Panel overlaid on side with film MDO 367 g/m2 boards for concrete forming

General Specifications

-

Allows up to 10 to reuses in the MDO face (requires reasonable care). Main face with MDO of 367 g/m2 and back face doesn´t have paper.

-

35% phenolic resin in MDO.

Product Features and Applications

-

Tulsa MDO Concrete Forming panels are edge sealed during manufacturing. If you have to cut boards during use, it is recommended to re-seal the fresh edges to avoid panel damage caused by capillary penetration of humidity.

-

Make sure to also use the appropriate form remover or release agent (a chemical reactive releases for nonporous surfaces).

-

Although cleaning a Tulsa MDO Concrete Form panel is much easier and quicker than traditional form material, it is important to only use fiber spatulas and synthetic materials when cleaning forms to prevent damages to the faces.This damage might occur when using metallic tools. Always store the panels inside a warehouse, protected from weather conditions.

-

While MDO Concrete Forming panels are very resistant to the abrasion and impact, care must be taken during cleaning and use to prevent damage. Always use the appropriate vibrators and techniques to protect the panel surface.

Size

Thickness:

-

12 mm = 15 / 32''

-

15 mm = 19 / 32''

-

18 mm = 23 / 32''

-

21 mm = 27 / 32''

Dimensions:

-

Width 1,220 m = 4'

-

Length 2,440 m = 8'

-

Width 1,250 m = 4 3/22

-

Length 2,500 m = 8 13/64

HDO 100/100

OVERLAID BOARDS FOR CONCRETE FORM

Phenolic Film Panel

Panel overlaid both sides with HDO 168 g/m2 + MDO 235 g/m2, with backer 168 g/m2, 15 to 25 reuses per face.

General Specifications

-

Allows between 15 to 25 reuses (requires reasonable care).

-

Its faces have 168 g/m2 high density film + 235 g/m2 MDO film overlaid, with a total of 403 g/m2 in every face (100/100) providing a high quality that assures water resistance and stiffness stability.

-

65% Phenolic resin in overlay film and 27% in MDO.

Product Features and Applications

-

Tulsa HDO panels are edge sealed during manufacturing. If you have to cut boards during use, it is recommended to re-seal the fresh edges to avoid panel damage caused by capillary penetration of humidity.

-

Make sure to also use the appropriate form remover or release agent (a chemical reactive releases for nonporous surfaces).

-

Although cleaning a Tulsa overlaid panel is much easier and quicker than traditional form material, it is important to use only fiber spatulas and synthetic materials when cleaning forms to prevent damages on the faces. This damage might occur when using metallic tools. Always store the panels inside a warehouse, protected from weather conditions.

-

While Tulsa HDO Overlays Panels are very resistant to the abrasion and impact, care must be taken during cleaning and use to prevent damage. Always use appropriate vibrators and techniques to protect the panel surface.

Size

Thickness:

-

12 mm = 15 / 32''

-

15 mm = 19 / 32''

-

18 mm = 23 / 32''

Dimentions:

-

Width 1,220 m = 4'

-

Length 2,440 m = 8'

HDO 100/30

OVERLAID BOARDS FOR CONCRETE FORMING

Panel overlaid on side with film HDO 168 g/m2 + 235 g/m2 MDO with backer HDO 168 g/m2.

General Specifications

-

Allows between 15 to 25 reuses (requires reasonable care).

-

Its main face has 168 g/m2 high density film + 235 g/m2 MDO film overlay, providing a high quality that assures water resistance, stiffness and stability, its back has 168 g/m2 high density film.

-

65% Phenolic resin in overlay film and 27% in MDO.

Product Features and Applications

-

Tulsa HDO panels are edge sealed during manufacturing. If you have to cut boards during use, it is recommended to re-seal the fresh edges to avoid panel damage caused by capillary penetration of humidity.

-

Make sure to also use the appropriate form remover or release agent (a chemical reactive releases for nonporous surfaces).

-

Although cleaning a Tulsa HDO Panel overlaid panel is much easier and quicker than traditional form material, it is important to use only fiber spatulas and synthetic materials when cleaning forms to prevent damages on the faces.This damage might occur when using metallic tools. Always store the panels inside a warehouse, protected from weather conditions.

-

While Tulsa HDO Overlay Panel are very resistant to the abrasion and impact, care must be taken during cleaning and use to prevent damage. Always use appropriate vibrators and techniques to protect the panel surface.

Size

Thickness:

-

12 mm = 15 / 32''

-

15 mm = 19 / 32''

-

18 mm = 23 / 32''

Dimensions:

-

Width 1,220 m = 4'

-

Length 2,440 m = 8'